Description

The main points

- Lowest emission values in accordance with or reliably below country-specific emission regulations, e.g. BImSchV (German Federal Ordinance on Exposure Control)

- High efficiency due to low residual oxygen in the exhaust gas, even under high emission requirements

- Extremely efficient, sound absorbing fan (monoblock) with low current consumption

- Complies with CE directives, type-tested

- Durable, modular design

- Straightforward mounting, commissioning and maintenance

- Suitable for various heat generators

- Available as a natural gas, light oil or dual fuel burner with the option of simultaneous operation of two fuels and combustion special fuel gases

- Design for air preheating (optional)

- Integrated combustion management system (optional)

- Further modular system extensions possible (optional)

Modular flexibility for minimum emissions as well as maximum availability and efficiency

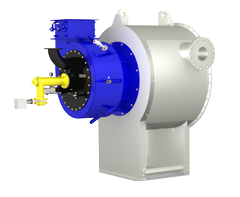

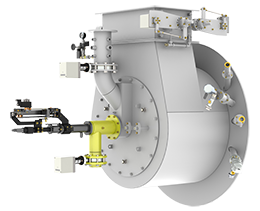

The SAACKE TEMINOX GL burner combines all the benefits of a modern combustion plant for industrial heat and steam generation. The burner is available in monoblock or duoblock design and for gas or light oil operation with unrivaled burner capacities up to 28 MW. The compact TEMINOX GL is delivered ready for connection, and can be flexibly configured with the following options:

- use of special fuels

- integrated SAACKE se@vis control

- speed control

- O2 control

The sophisticated design of the mixing system, the variability in the nozzle geometry and the adjustable stabilizing plate ensure a high control range and the lowest NOX emissions in gas and oil operation. The standard design is equipped with an electronic fuel-air compound control. The monoblock version has an integrated high-performance fan designed specifically for the burner, which, together with the energy efficient motors achieves outstanding efficiency and overcomes large flue gas-side draft losses. The duoblock version provides the additional option of use with preheated combustion air. The optional double gas ring also enables the simultaneous combustion of two different gases.

This equipment in combination with its modular flexibility makes the SAACKE burner “Made in Germany” an attractive solution with respect to technology as well as cost effectiveness for environmentally conscious customers.