Description

The main points

- Easy installation in the channel between the gas turbine and heat generator

- Especially low pressure loss

- Can be installed as a “channel burner” upstream from a waste heat boiler

- Can be installed as a “boiler burner” upstream from a boiler furnace

- Multiple burners can be arranged in one installation frame

- Available for numerous (special) fuels

- Very low emission level

- Combined operation / additional fresh air operation / fresh air operation possible

Flexible firing in axial arrangement

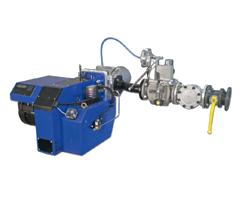

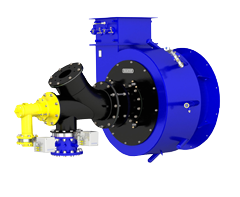

The DDZG steam pressure atomizer series is sturdy, proven and variable. It can be adapted to numerous requirements and therefore forms the basis of the DDZG A channel burner series. In this arrangement, media flow through the burner axially with the burner in a line between the gas turbine and heat generator.

The burner can either fire into the channel (“channel combustion chamber”) or can be mounted directly on a waste heat boiler. The burner is located in a burner installation frame with diaphragm dampers, which ensure optimum flow guiding of the gas turbine flue gases or fresh air. Pressure loss is pleasantly low, just a few millibars. The dampers in the diaphragm frame are closed as soon as the burner is firing in fresh air mode and are opened to use turbine flue gas. Fuel oil, gas and primary air are supplied from outside.

If full heat capacity is required in partial load operation, the turbine flue gas and fresh air can also be mixed, which considerably enlarges the control range of the plant. Multiple burners can also be installed in one burner installation frame. In this case the flame is especially short and ideally suited for compact furnaces.

It goes without saying that the DDZG A combusts even problematic fuels completely and with low emissions, and that the burner’s robust design requires little maintenance with a very long service life.

With all its flexibility, the DDZG is uncompromising in just two attributes: high quality and extremely long service life.