Description

The main points

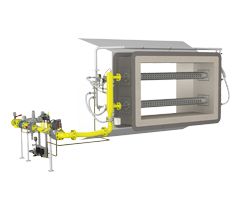

- Easy retrofitting of existing heat generators as well as short downtime for installation and commissioning

- Long maintenance intervals for turbine and burner

- High system availability

- Very low emission levels and quick ROI thanks to outstanding efficiency

- Designed for all standard and special liquid and gas fuels such as biogas

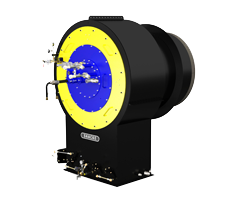

- Turbine and burner can be operated independently

- Increased production flexibility and independence of energy cost fluctuations

Micro-CHP-System: energy-efficient electrical power and heat generation

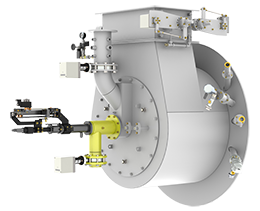

Until now, small to medium-scale combined heat and power (CHP) generation was usually realized in cogeneration plants, which are unfortunately very maintenance-intensive. As an alternative, SAACKE is offering an extremely low-maintenance special burner from the DDZG-GTM line for these types of CHP projects. A gas turbine generates 50 to 1,000 kW electrical power. The high-energy turbine gas, which is fired in the downstream heat generator, is utilized up to 100 percent as combustion air in the DDZG-GTM SAACKE gas turbine exhaust burner. Depending on design and configuration of the heat generator, this type of CHP system generates heat, steam or hot water – and produces valuable electrical energy. This combination of turbine and burner always guarantees continuously low emission levels which are reliably below requirements across the entire range of EU regulations.