Description

The main points

- Makes it possible to use dust as an inexpensive fuel

- Can replace valuable standard fuels

- Extremely low emission values at all firing rates

- Very short, stable flame which can be controlled well

- No support fuel required

- Short amortization time

Using dust and by-products as cost-effective fuels

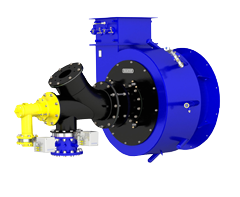

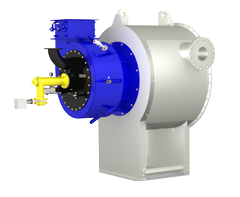

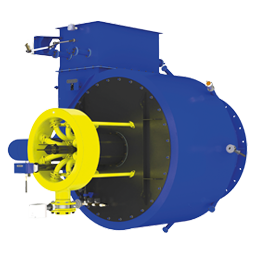

In times of uncertain price trends for standard fuels and increasing demanding emission values, dust combustion systems can lower operating costs and form a reliable foundation for generating heat. The SSB-D swirl burner series shows its full potential here, offering economical firing in combustion chamber operation with optimum burnout and low flue gas values. It is based on a swirl burner (SSB) with its characteristic tangential windbox, which ensures the especially strong swirl and the extremely short flame.

As soon as the heat generator has warmed up in gas firing operation mode, the dust can provide the required heat: After brief simultaneous firing mode with gas and dust, the dust flame burns absolutely stably – without any support fuel. In dust mode the heat generator responds like a conventional combustion system, offering a control range of 1:3 or better. Dust burnout is outstanding at every firing rate and the NOx and CO emission values are reliably below all limit values.

NOx emissions are also especially low on water-tube boilers in combination with a muffle and multistage combustion air supply, often making secondary measures for reducing NOx (for example SNCR) superfluous.

Even if the equipment overhead for a dust combustion system requires higher investment costs for the silo and dust transport, deriving heat from carbon dust, wood dust or petroleum coke quickly pays for itself. The amortization times are even shorter if by-products can be utilized which would otherwise have to be disposed of in expensive processes. In principle all pulverized fuels with a particle size < 0.5 mm can be used for this purpose. In actual practice, fuels include post-extraction canola meal, soy husks, coffee husks or wood sanding dust.

Because the SSB-D is part of the swirl burner product family, it offers all the advantages of that flexible series. Additional fuels can also be added, including variants that fire oil, two gases and dust, if necessary even simultaneously. The specific variant or size and the type of dust that is used do not play a significant role: Deciding to use the SSB-D always lays the ground work for highly available and affordable firing.

The high energy efficiency and low maintenance cost represent the results of decades of continuous development work.

With all its flexibility, the SSB-D is uncompromising in just two attributes: high quality and extremely long service life.