Description

The main points

- Compact monoblock design with proven pressure atomizer technology

- Plug-and-play solution with excellent cost-benefit ratio

- All electrical components already plug-wired

- Superior performance figures

- Fast, uncomplicated planning, mounting and commissioning

- Service-friendly connections and easy to maintain

- Very short delivery period

- Comply with the latest requirements of the German Federal Ordinance on Exposure Control (1. BlmSchV) and the Russian GOST certification

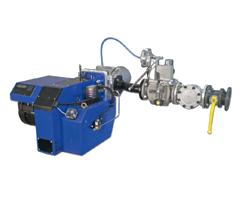

Plug-and-Play solution in the lower capacity range

High operational reliability, compliance with emission regulations, and exibility in terms of fuels and costs – even in the lower capacity range, these aspects have utmost importance. For this reason, SAACKE has introduced the Tx burner series. The compact burner is based on pressure jet technology and is available in three different versions: As oil (Tx-L), gas (Tx-G) or dual fuel burner (Tx-GL).

With the Tx, SAACKE – a specialist for individual and customized combustion systems – offers a plug-and-play solution in the lower capacity range. The burner, in monoblock design, is supplied preset and pre-assembled for easy and fast commissioning. Superior performance gures give the Tx series an excellent cost-bene fit ratio.

The Tx is characterized by its compact design. The equipment varies depending on the fuel type. The oil burners fan compartments have a telescope opening device, and the oil pump is driven directly by the fan motor. The pressure jet gun has one or two oil nozzles, depending on the size. In the dual fuel burner, the pump assembly has its own drive motor. The model is always supplied in a single-pipe system and can be adjusted on site if required. The Tx can be supplied within a very short delivery period.

All electrical components are mounted directly on the burner – an external switch cabinet is not required. For size 20 and higher, the burner also has a side-mounted control box that is already plug-wired. Tx burners have two stages for fuel oil and either a two-stage sliding or modulating design for gas. The Tx-G has a pneumatic compound that adjusts the gas volume ow to the air ow using a pressure control valve. During commissioning, only the maximum and minimum load need to be set up, which leads to shorter start-up times.

The individual components of the burner are positioned for ease of service. Using a special quick-closing coupling, the oil supply can be disconnected for maintenance. For the gas and dual fuel burners, the burner housing can be swung open to the left or right, thus bringing it into the required maintenance position. In this way, all components of the mixing device are easily accessible.

In addition to the fan compartment, the precision mixing device is an essential component of the burner. It guides the air ow and mixes fuel and air in an optimum ratio. In the gas variant, the gas inlet can be either from the left or right. Burners of this series comply with the latest requirements of the German Federal Ordinance on Exposure Control (1. BlmSchV) and are CE-approved. In addition, they accord to further certi fications – for example the Russian GOST certification (EAC).